Specializing in Abusive Applications

Custom-Engineered Nagle Pumps For Cost Efficient Pump Solutions

For more than 70 years, Nagle Pumps has been the standard of excellence and reliability in heavy-duty pumps for abrasive, corrosive and high temperature applications. At Nagle, we offer a wide selection of designs, components, and materials of construction to custom engineer each pump to meet your specific requirements.

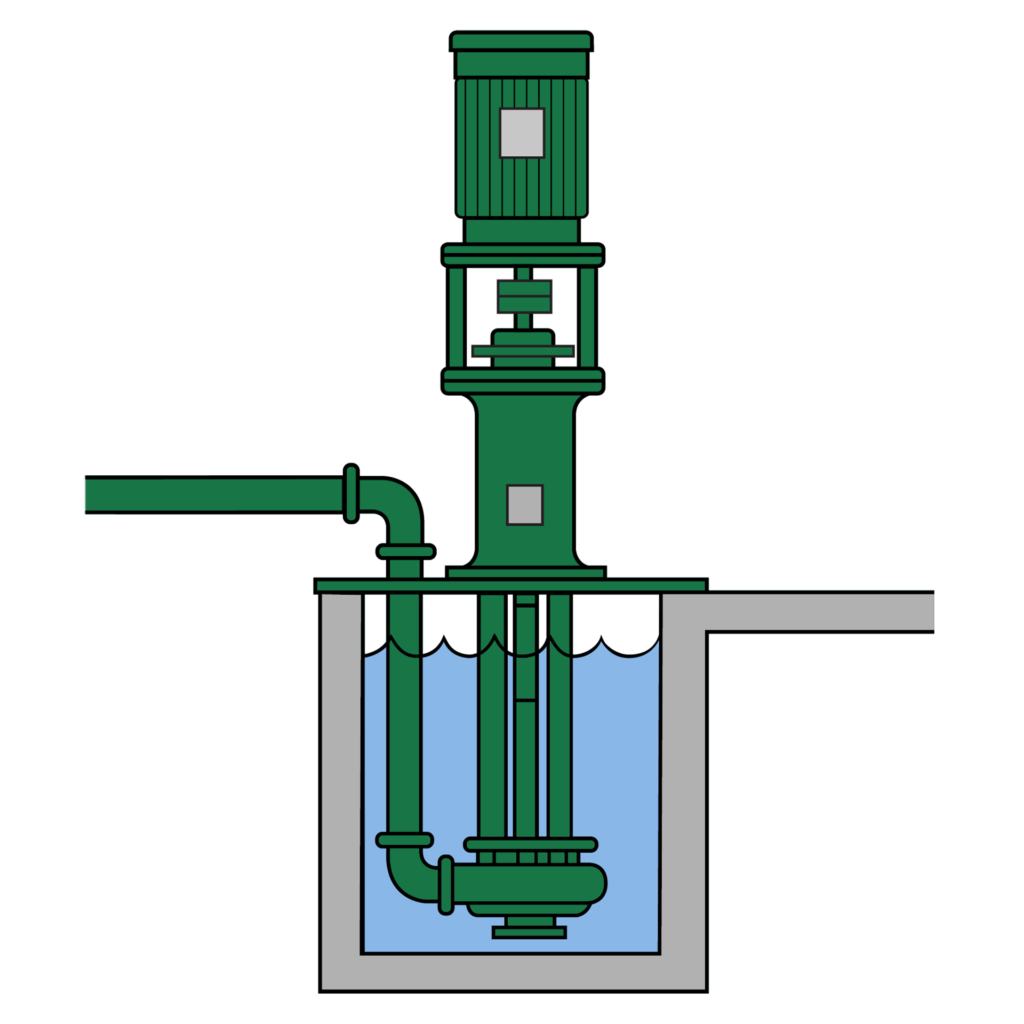

Vertical Cantilever

Vertical cantilever pumps are designed with a true cantilever shaft. There are no submerged bearings, bushings, packing or seals below the mounting plate exposed to the pumpage.

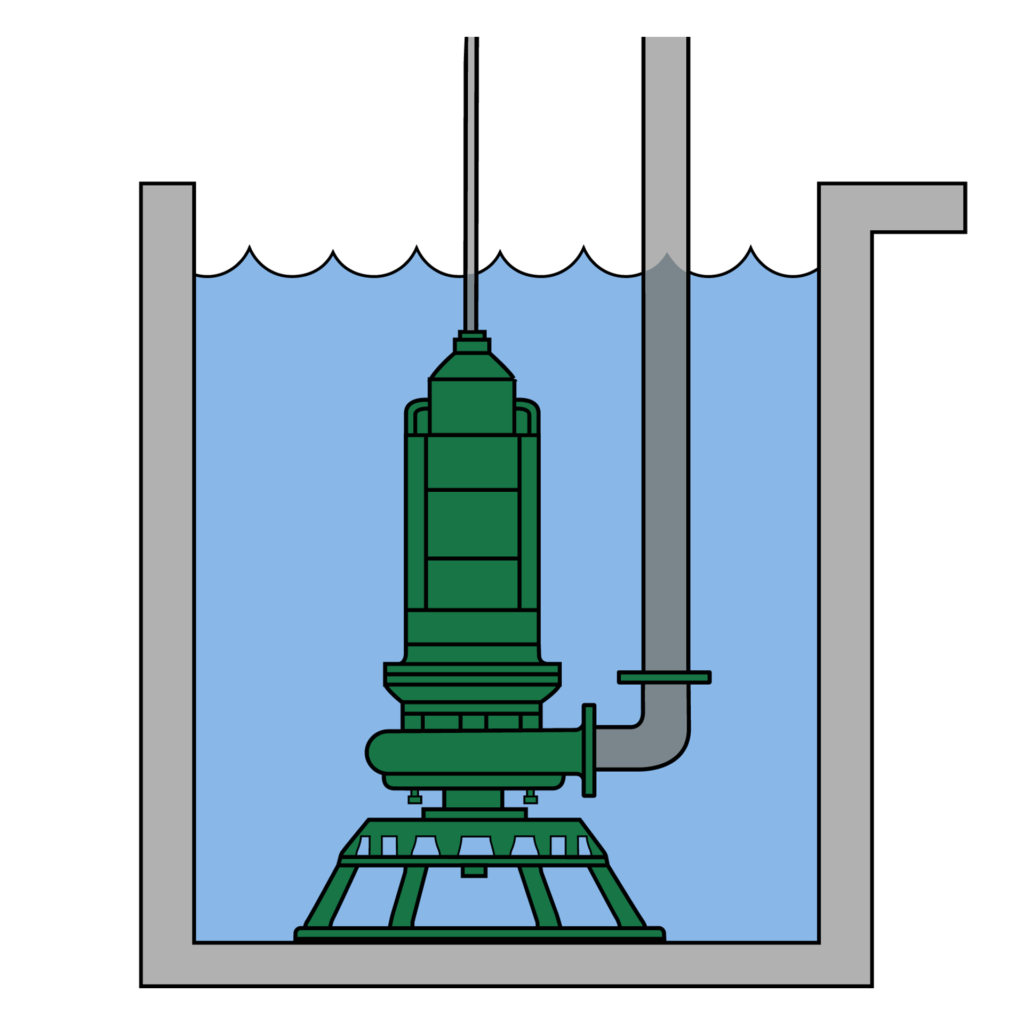

Vertical Submersible

Vertical submersible pumps tolerate a wide range of abrasive and corrosive applications. The design eliminates the need for head room, mounting pedestals, long columns and tail pipes, saving space and money.

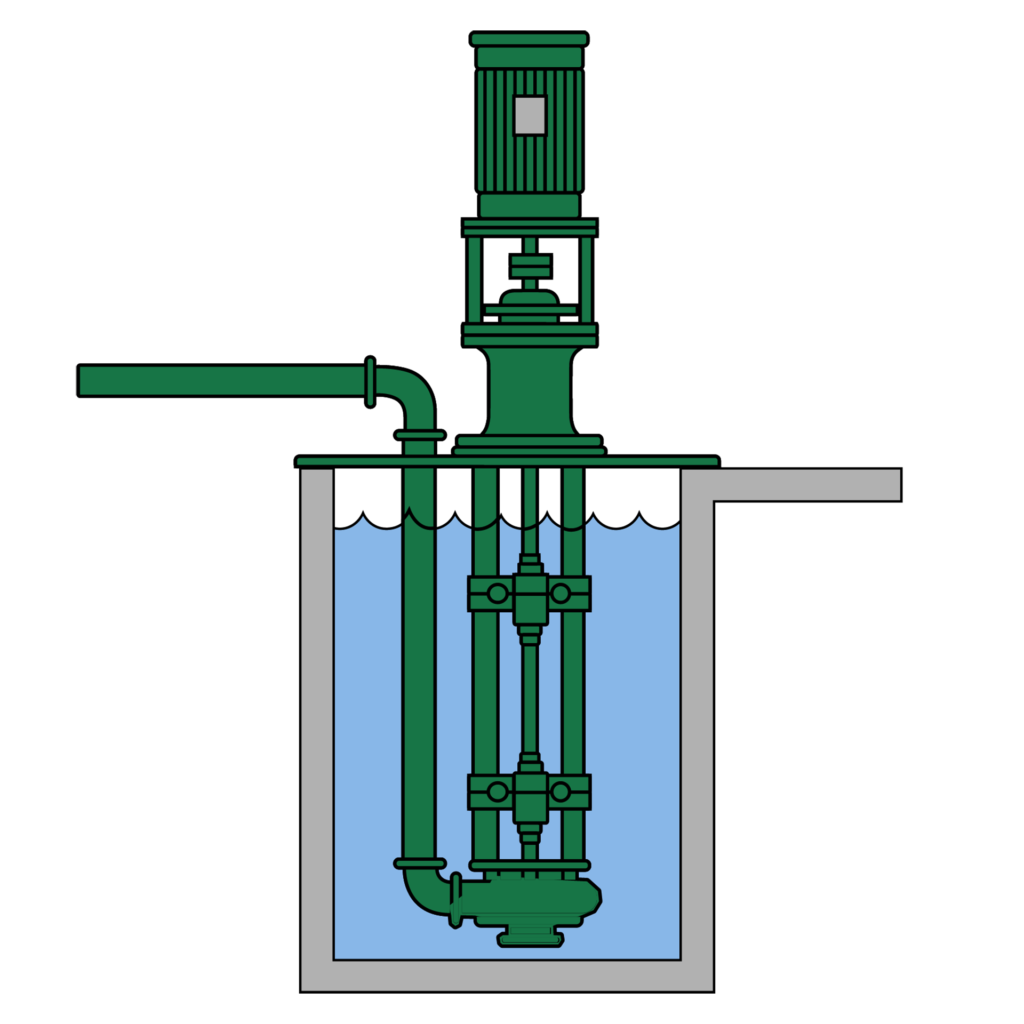

Vertical Submerged Bearing

Vertical submerged bearing pumps provide slurry handling with easy maintenance features. Designed for wet pit use, slurry pumps can be customized with top or bottom suction.

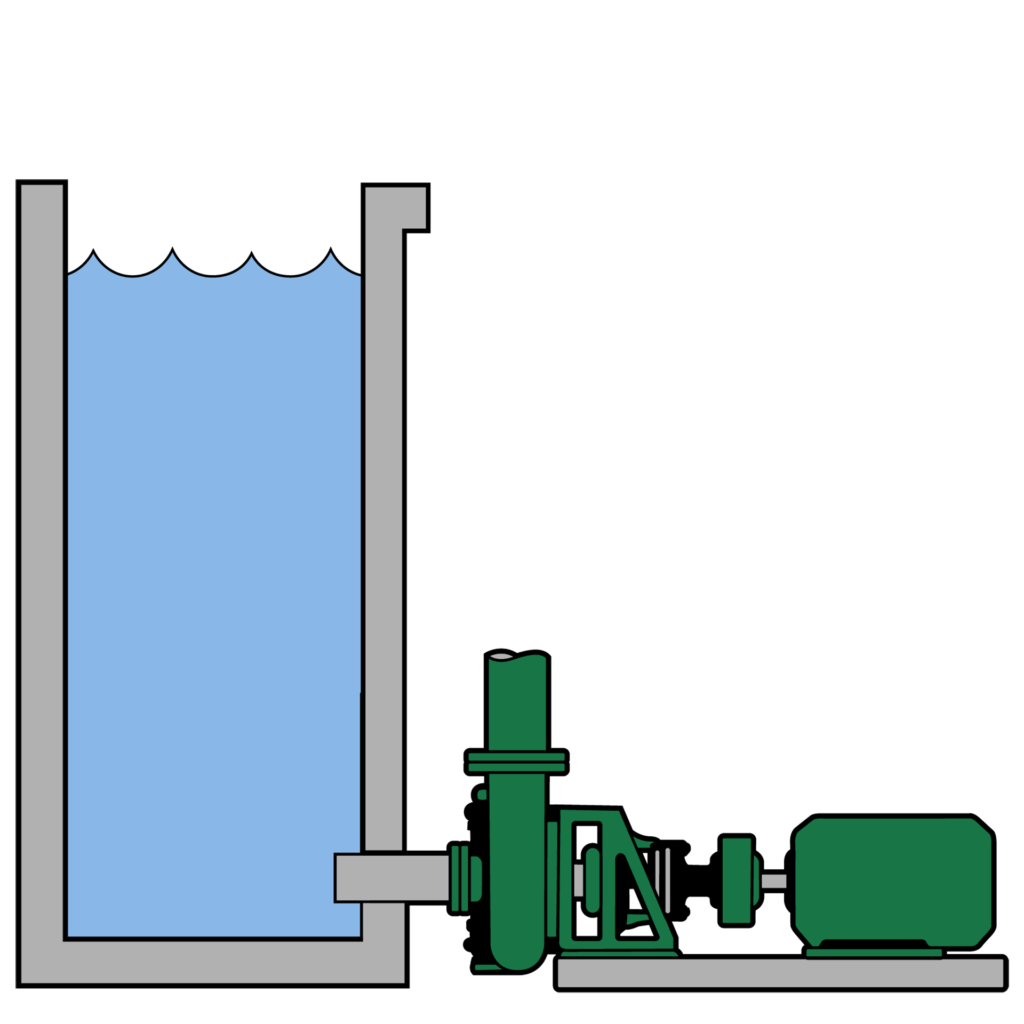

Horizontal Heavy Duty

Horizontal pumps are compact with an enclosed bearing frame design. Advanced large passage impellers provide maximum solids handling with reduced wear.