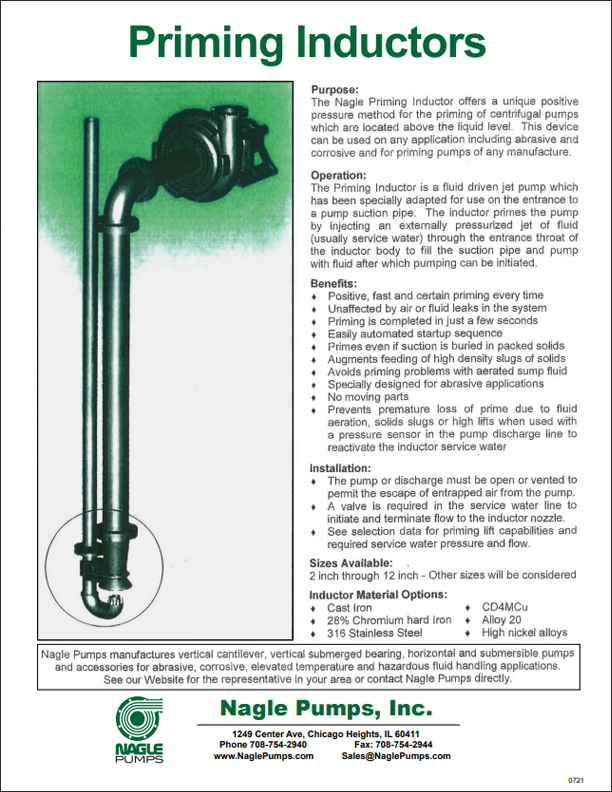

Priming Inductor

The Nagle Priming Inductor uses positive pressure to prime centrifugal pumps located above the liquid level. This device can be used on any application including abrasive and corrosive fluids. The Priming Inductor is compatible with any manufacturer’s pumps.

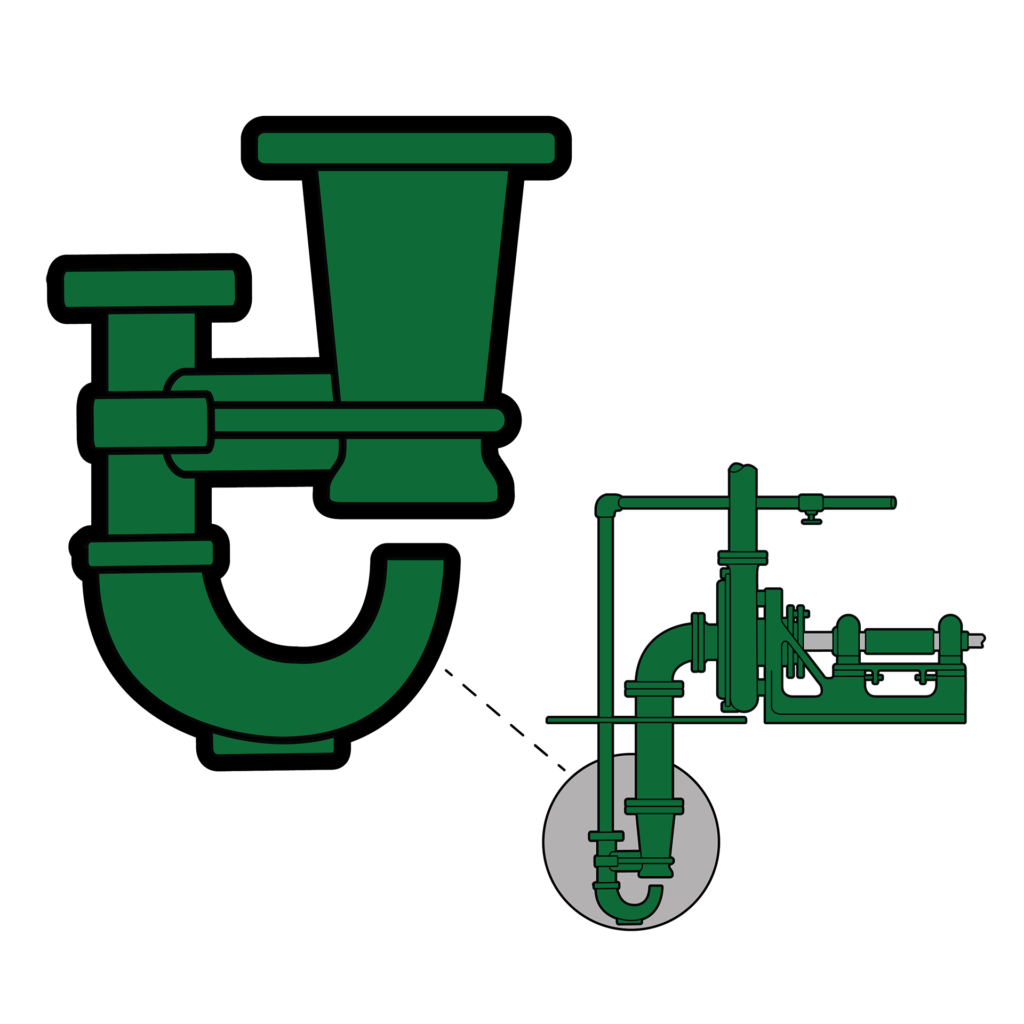

The Priming Inductor is a fluid driven jet pump specially adapted for use on the entrance to a pump suction pipe. The inductor primes the process pump by injecting an externally pressurized jet of fluid (usually service water) through the entrance throat of the inductor body to fill the suction pipe and pump with fluid. After priming, the main process pump can be started.

When paired with a pressure sensor in the discharge line, the Priming Inductor prevents premature loss of prime due to fluid aeration, solids slugs, or high lifts. In this configuration, the sensor can activate the inductor service water to maintain continuous prime.

Sizes: 1.5″ through 12″

Materials: Cast Iron, CD4MCu, HC28, Alloy 20, 316SS, High Nickel Alloys

Benefits

- Process pumps are primed in just seconds

- Unaffected by air or fluid leaks in the system

- No moving parts

- Easily automated start up sequence

- Primes even if suction is buried in packed solids

- Augments feed of high density slugs of solids

- Avoids priming problems with aerated sump fluids

- Specially designed for abrasive applications